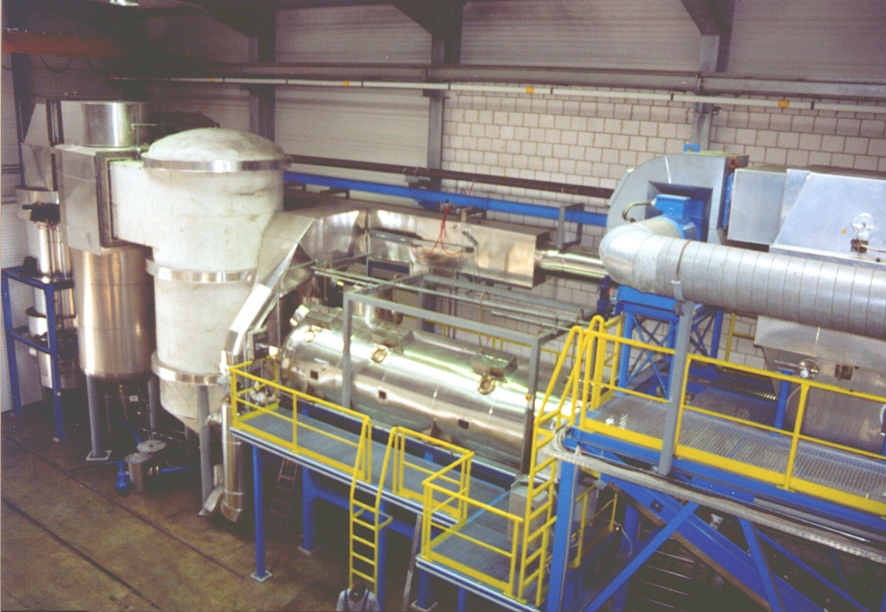

With the start of the project in 1998 and the construction of the first SGL plant of TCP Energies GmbH & Co. KG on an industrial scale (1:1), a new technological solution approach was developed based on modified thermolysis with direct coupling of gasification.

The basis was the building permit for the construction of a multi-chamber thermolysis plant "PR 450 Technikum". After a successful series of tests and inspections, the notice of approval 09/03 was issued in accordance with § 4 Para. 1 BImSchG (Federal Immission Control Act) in conjunction with. § 2 para. 3 of the 4th regulation of the BImSchG (4th BImSchV) dated 05.11.2003 and 12.09.2011 The following premises were defined in terms of development technology:

- No process interruption due to stock discharge

- Available standard single apparatuses are purchased in addition

- Suitable individual apparatuses are modified

- Individual apparatus for core components are developed in-house

The RDF with the newly developed Duplex Turbulent Expansive Carbonbed - Process (Duplex TEC-Process®) worked in various research campaigns during the operational period between the years 2000 and 2011.

Between 2000 and 2002, the objectives were essentially to demonstrate mechanical functionality in thermal operation and to produce a high-calorific synthesis gas.

In 2003 and 2004, special campaigns were run on processing technology and drying, and from 2005 onwards the engine design of the synthesis gas system was carried out.

Between 2007 and 2008, the further development of individual apparatuses (thermolysis chamber, gasifier, gas purification, etc.), including the design of turnkey plants, took place during operation. This was accompanied by mathematical modeling with complex mass, energy and material balancing, supported by model tests on thermodynamic behavior.

Between 2008 and 2010, campaigns were carried out to increase throughput and improve gas quality and performance by blending pure oxygen into the gasification agent, ambient air.